A lot was accomplished in September. Most of the remaining work was cosmetic.

The above shows some more filling with Pettit Watertite epoxy filler on the air scoops / dashboard.

The seam along the rear deck was fiberglassed over.

| ||||||

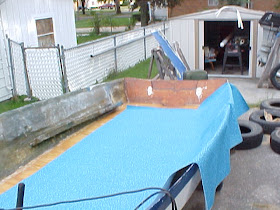

I finally unrolled the Nautolex vinyl flooring and fitted it into the boat. It is waterproof and was later laminated in with flooring adhesive.

You'll see shop lights laying face down in the boat. This was to evaporate water that soaked into some fiberglass weave where the plywood deck meets the hull. A big pain but the problem is fixed.

Time to set the original foot rest into the boat. It will be expoxied in after the flooring is in.

The sides of the rear deck were cut from the cardboard patterns and fitted in.

Here is a big 'oops' that added days to the project; large gaps between the sides and topside plywood!

Later I laminated fiberglass cloth underneath and added generous amounts of woodflower/poly resin. This resulted in days and days of putting off the hours of sanding needed to get the contour right.

A lucky find! Two more 'sleeper seats' on the side of the road. These will help out a lot when making the new ones!

The front of the deck was painted with Pettit thick white undercoater primer.

The Nautolex vinyl flooring was laminated in. A bigger hassle than I thought it would be because I did it without the rolling tool. A big mess but all turned out okay.

The foot rest supports were epoxied in place.

The first coat of Pettit EasyPoxy Electric Blue paint was rolled and tipped on the front end.

Loads of polyester resin mixed with wood flower filled in the big 'oops'!

Getting ready for the fin.

The cardboard, three poles and string were to help establish the contour of the deck for making the fin. The string down the center marked the level line between the front and back. The string at the rear provided consistent height from front to back.

After the contour line was drawn the pattern for the fin was drawn on 1/4 exterior grade douglass fir ply then the contour of the deck was added underneath.

After about a year after I bought them its time to finally get the last of the 4 x 8 foot plywood out of the house!

If anyone is going to take on a project like this it helps to have a garage, which I don't have.

Lots of good , dry scrap wood accumulated after three years of working on the boat. The wood working portion of the boat was coming to an end so I put an ad in Craigslist for free project wood. A friendly and nice family drove nearly 45 minutes to come over and load up their truck.

My porch was a mess. Another reason for needing a garage... however noone could see it from the street. :)

No comments:

Post a Comment